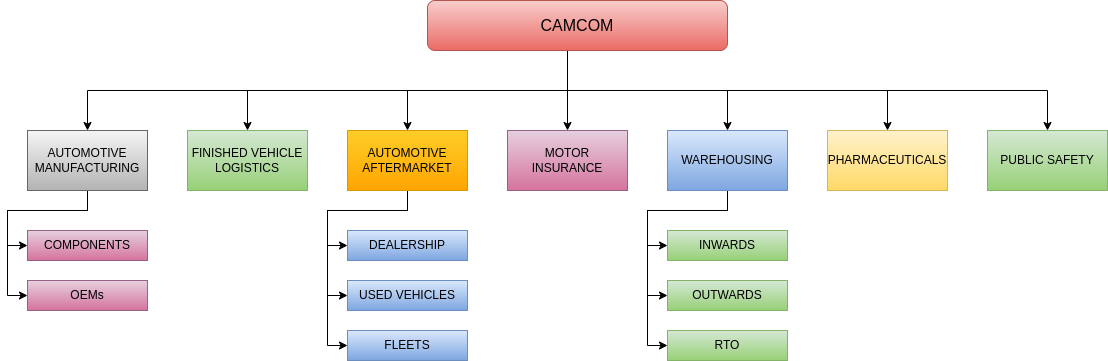

CamCom's Role in Industry Solutions

Automotive

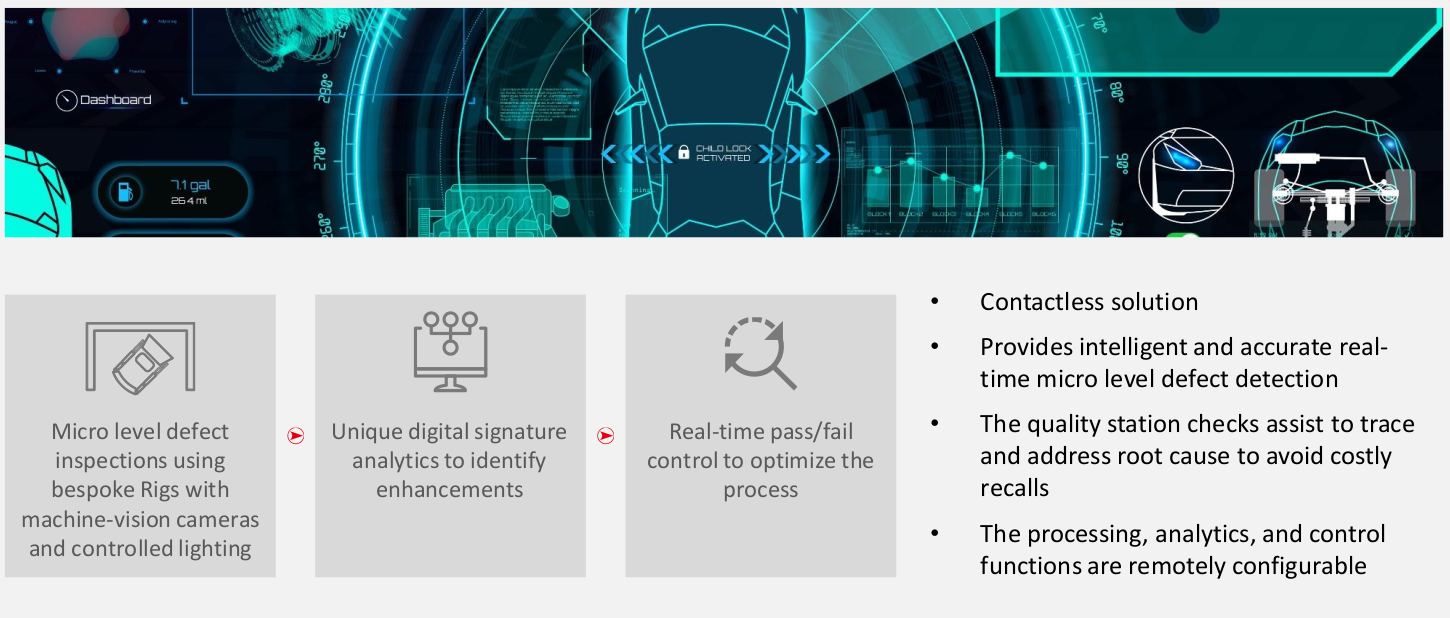

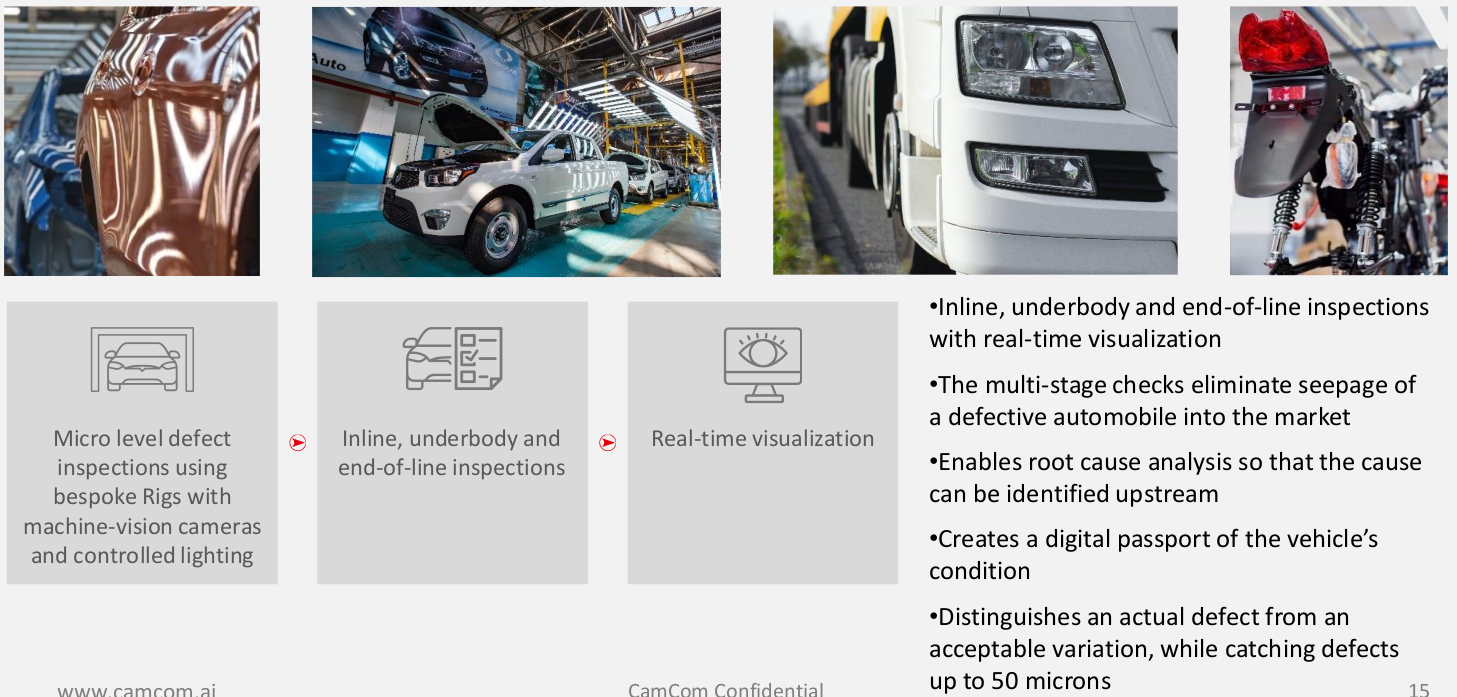

Automotive Manufacturing - Components

Automotive Manufacturing - OEMs

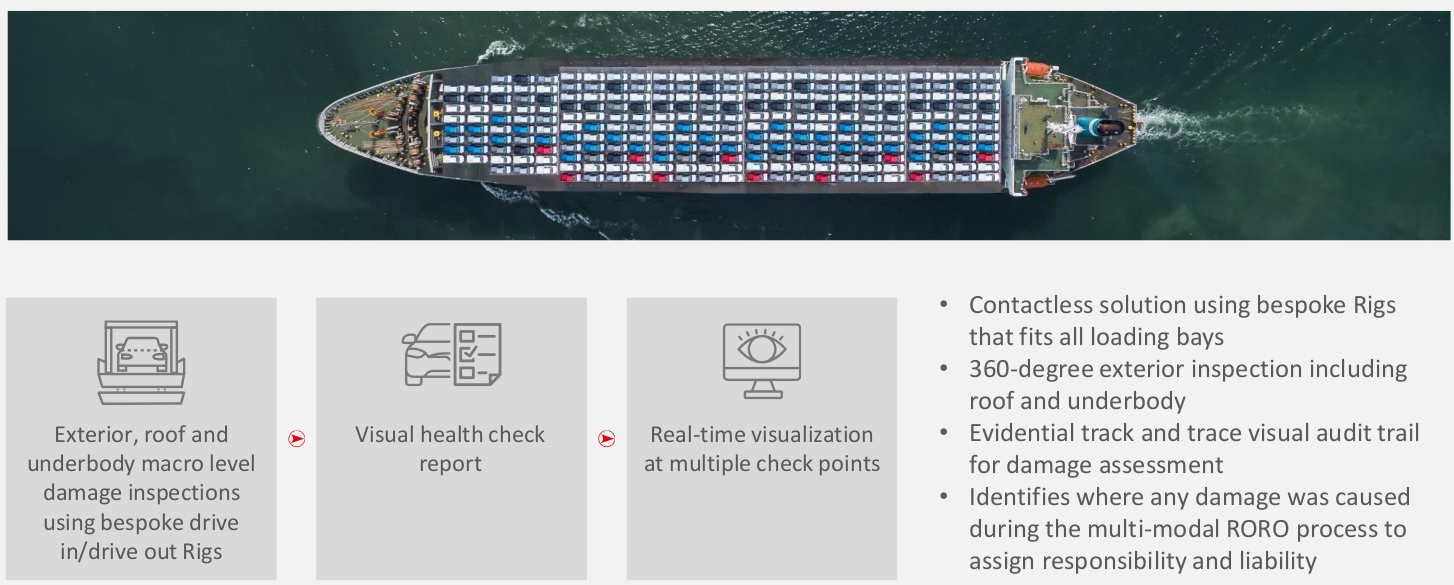

Finished Vehicle Logistics

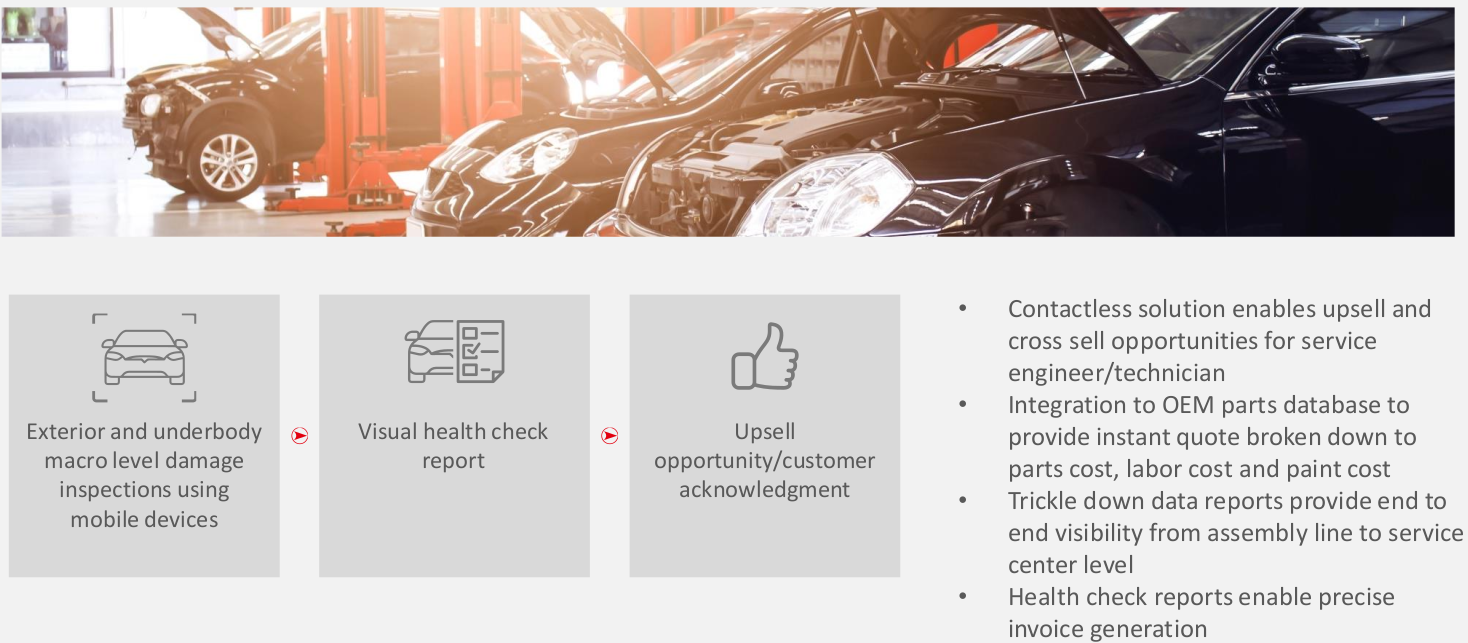

Automotive Aftermarket - Dealership and Service Centers

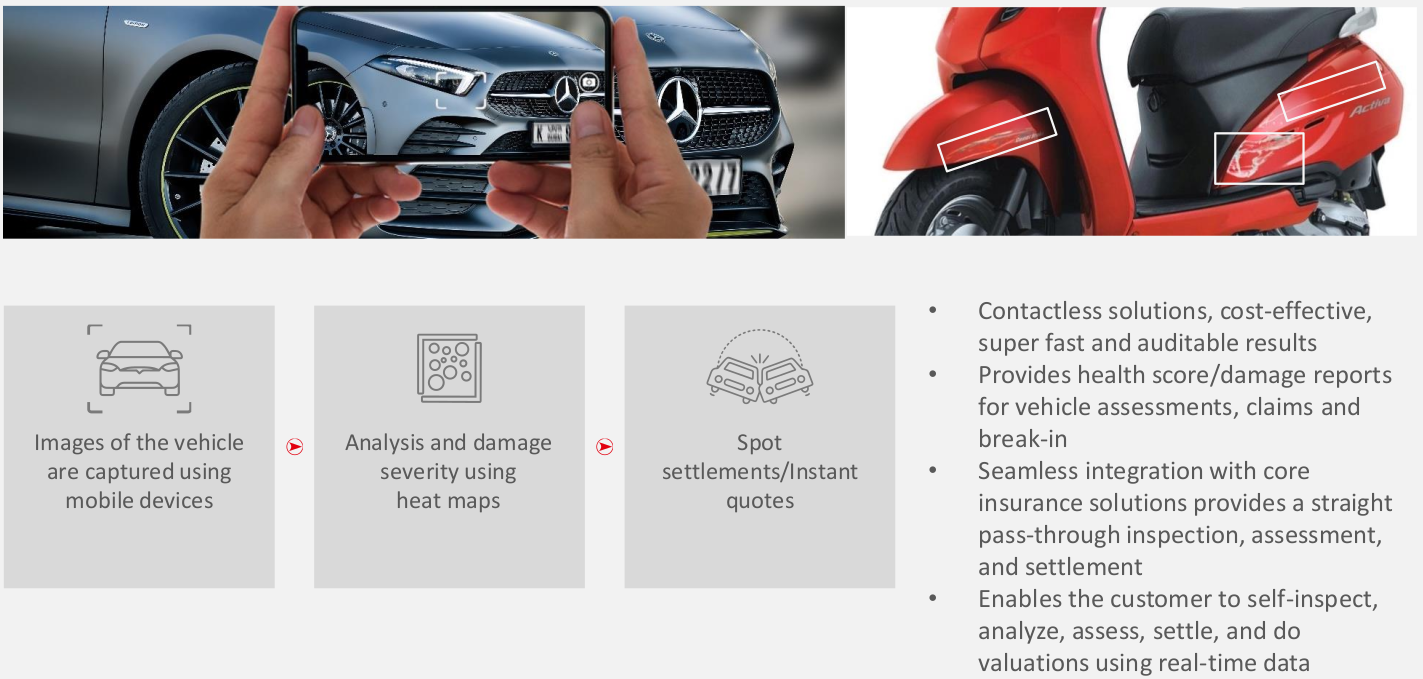

Automotive Aftermarket - Used Vehicles

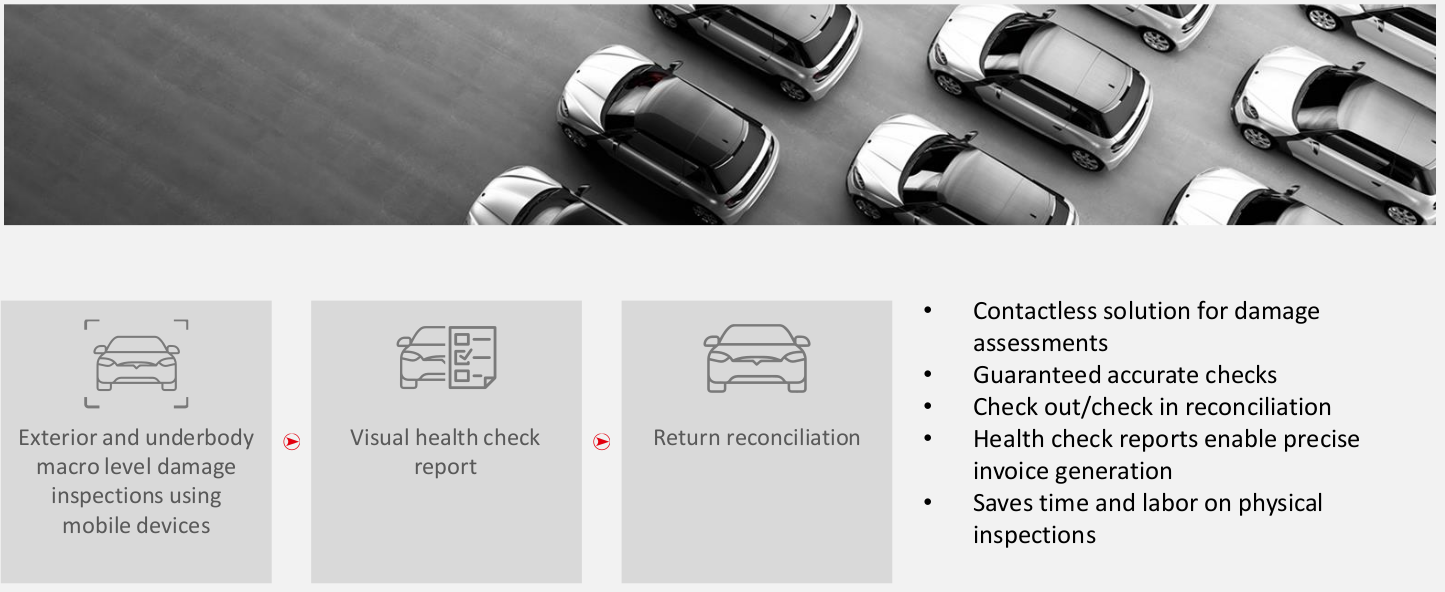

Automotive Aftermarket - Fleets / Car Rentals

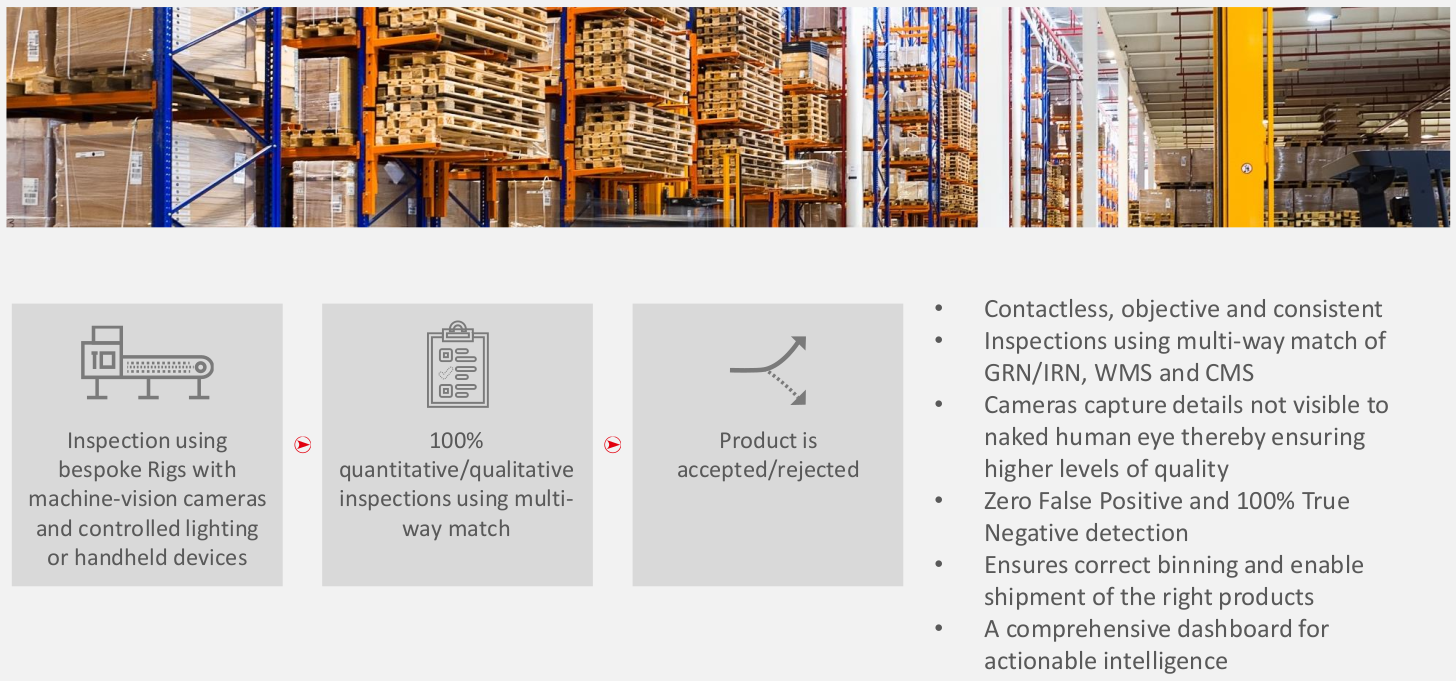

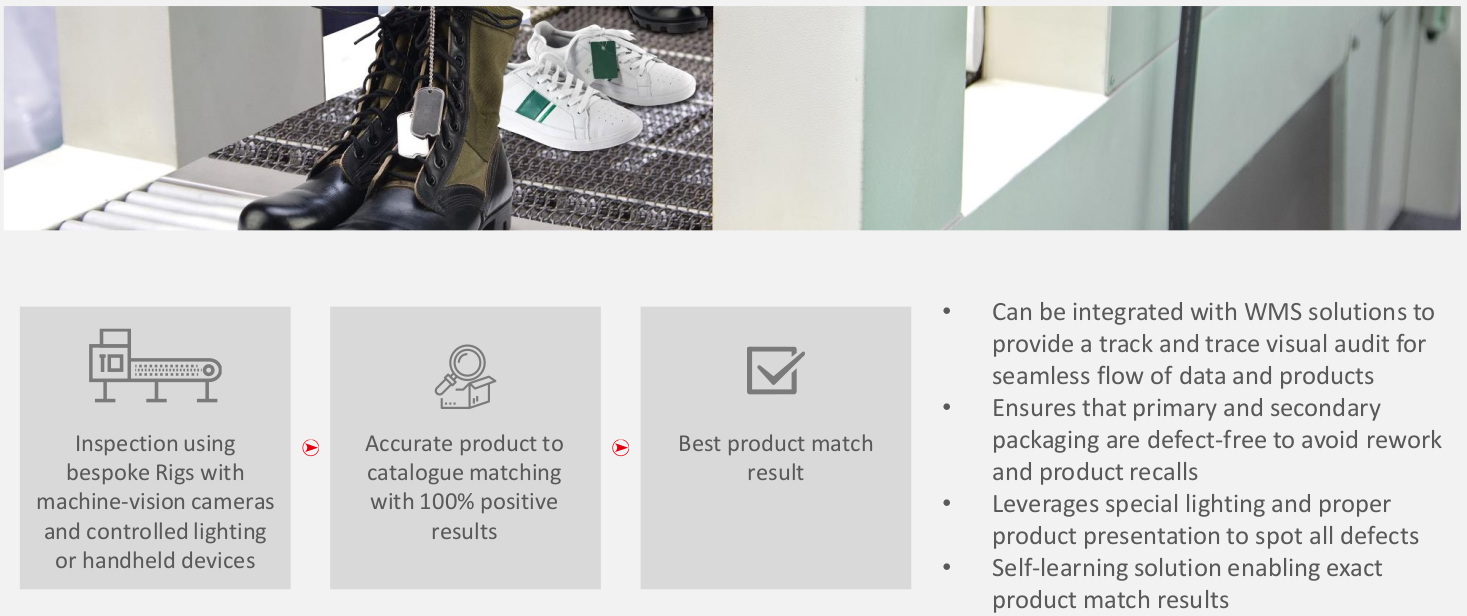

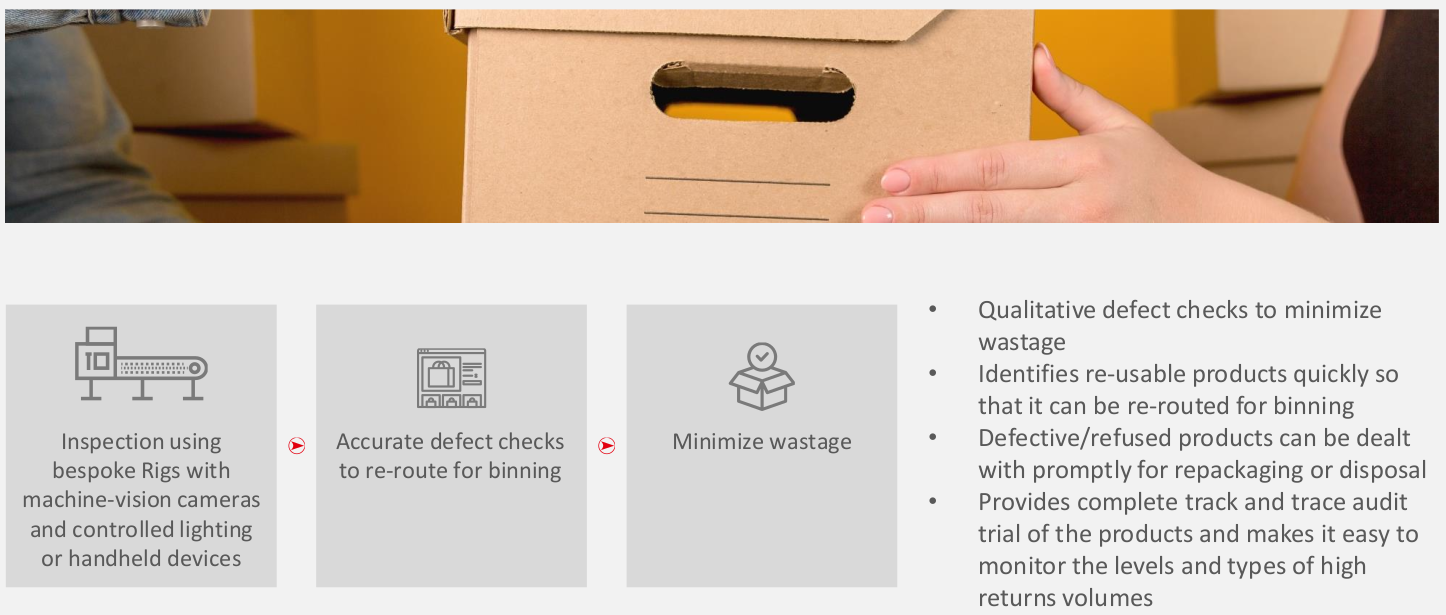

Warehousing

CamCom’s platform is designed to improve warehousing operations.

Inwards

Outwards

Return to Origin (RTO)

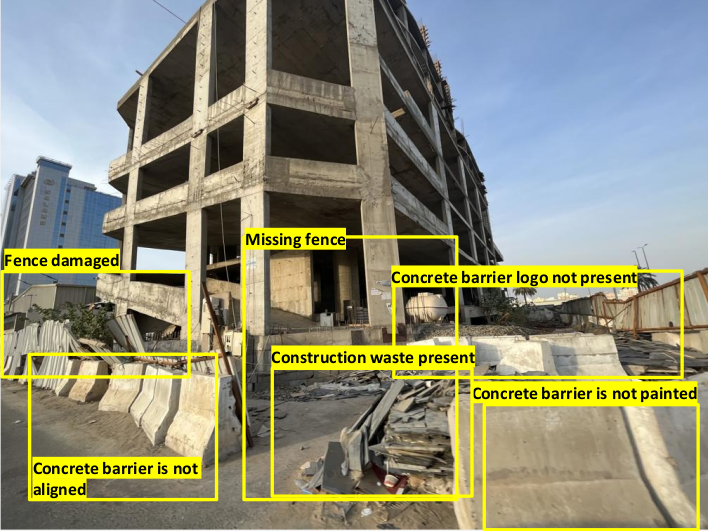

Public Safety

Visual Pollution (VP)

Visual pollution refers to any disruption in landscapes caused by elements that detract from aesthetic appeal or limit movement. CamCom’s Computer Vision platform helps detect and classify elements like construction waste, manhole issues, and road cave-ins, supporting efforts to meet UN Sustainable Development Goals (SDGs).

Benefits

Pharmaceuticals

In the pharmaceutical industry, CamCom ensures accurate tracking and traceability through character inspections.

Character Inspections for Accurate Tracking and Traceability

Visual inspections in the pharmaceutical industry include named entity recognition (NER), which is used for accurate data comparisons to ensure that pharmaceutical companies can promptly dispose of expired products. The use of AI in the pharmaceutical industry identifies, verifies, traces, and tracks character codes and data. The AI-powered OCR technology can also ensure the correctness of printed labels, which is especially important in pharmaceutical manufacturing. The latest deep learning technology is used to read complex and difficult-to-read characters. The automated visual inspection process in pharma guarantees over 98% read rates, with over 97% accuracy in reading errors.

Benefits